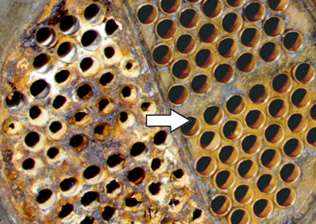

Chemical pre-cleaning activities generally consist of removal of

- Extraneous matter

- Dirt, dust, grease, oil

- Welding slag

- Loose rust and oxide scales

- Other debris that can form deposits within the system and interfere with operating equipments.

In addition to this, deposits also promote microbial growth and interfere with corrosion control measures. Our cleaning program involves use of

- Surfactants

- Dispersants and Biodispersants,

- Mild/strong inhibited inorganic acids,

- Organic acids

Selection of the cleaning agents is primarily dependent on the condition of the deposits.

VASU's chemical cleaning solutions include

- Pre-commissioning and pre-operation Cleaning

- Circulation and flushing

- Decommissioning Cleaning

- Specific Equipment Cleaning

After metal oxide layers are removed during cleaning, the equipment is prone to corrosion. Hence passivating chemicals are administered in the system to promote rapid formation of protective corrosion inhibitor film on the cleaned metal surfaces. Key reasons for passivation

- Effective passivation is imperative for optimum corrosion inhibition.

- Regular chemical treatment will function well only in the system where the initial passivation is correctly done

Optimal cleaning and passivation is combined with the following to ensure optimum efficacy

- Use of heat for better cleaning/passivation

- Flushing activities

- Continuous monitoring of influent/effluent water parameters

- Formation of loops for closed/open circulation

To provide a comprehensive solution for our clients’ cleaning needs VASU believes in 3P - People, Products and Processes

People

- Well trained & technically qualified staff to execute industrial cleaning jobs for process side, cooling water and boiler water systems

- Experienced chemists, analytical instruments and reagents required for analysis during the activity.

Products

- Chemistries to keep surfaces clean and protected for asset protection and less system downtime.

- Full range of products for pre-cleaning and passivation of process & water system.

Processes

- Cost-effective, efficient and safe Chemical cleaning methods which are custom designed solutions for your specific system needs

- Provision including installation and maintenance of all the requisite equipment such as pump sets, valves, flexible hose pipes, tanks, pipes and fabrication material etc.

VASU's Cleaning programs include Precleaning and Passivation. Both these processes are a critical preparatory component of commissioning activity before taking plant units and equipment online. Precleaning and passivation are also conducted after shutdown and turn around. These treatment programs are essential because pre start up actions can increase system life expectancy and efficiency and reduce corrosion and fouling in the long run.

VASU's Cleaning programs include Precleaning and Passivation. Both these processes are a critical preparatory component of commissioning activity before taking plant units and equipment online. Precleaning and passivation are also conducted after shutdown and turn around. These treatment programs are essential because pre start up actions can increase system life expectancy and efficiency and reduce corrosion and fouling in the long run.