Boiler Water Treatment

A boiler generates steam and is used to drive turbines to generate electricity. The steam reduced by the boiler is also used for various purposes including: Air Conditioning systems, heating hot water, process applications, driving steam engines and marine application. Large boilers are used for commercial, industrial, utility and many more applications.

Two types of boilers commonly used are

- Firetube boilers wherein the combustion gas passes inside the boiler tubes and heat is transferred to water between the tubes and the outer shell.

- Watertube boiler wherein the boiler water passes through the tubes, while the exhaust gases remain in the shell sides, passing over the tube surfaces. Usually, watertube boilers are used where high steam pressures are required.

Depending on the sources of heat, Water Heat Recovery Boiler (WHRB) and Heat Recovery Steam Generators are commonly used.

The major problems in the functioning of the boiler systems are both Corrosion and Deposition. Their effects are Scaling and Sludging, which lead to elevated metal temperature causing failures in tubes and restricted steam generation.

Moreover, Pitting and corrosion of pipes and tubes surfaces result in leakage of tubes, which significantly reduces steam production and system efficiently. The main objectives of effective boiler water treatment are

- Uninterrupted heat transfer

- Corrosion and scale control

- Generation of high quality steam.

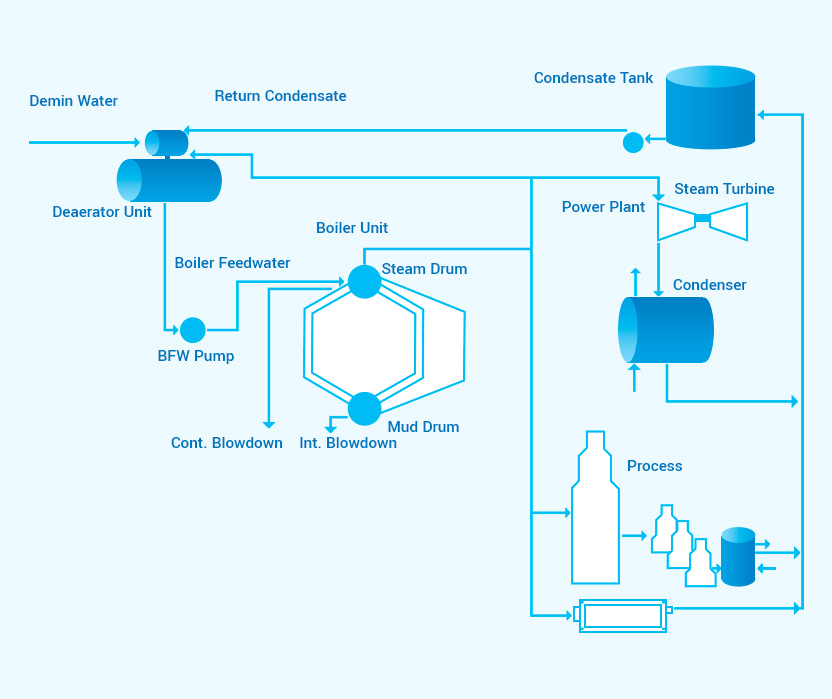

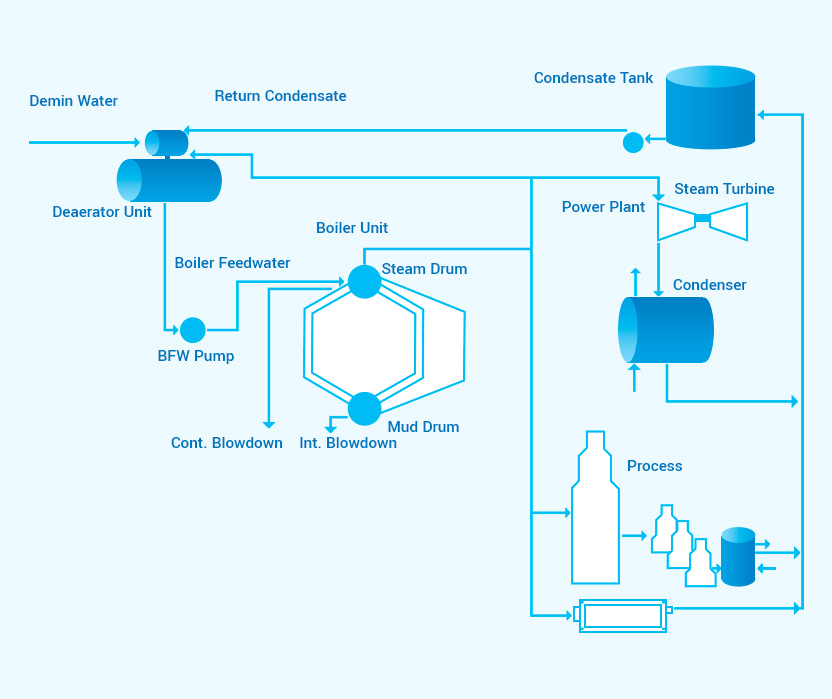

Typical boiler water treatment program

Oxygen Scavengers

These are used to remove the dissolved oxygen from the boiler feed water. They thus control the corrosion in the feed water tank and the condensate return lines. VASU offers specifically formulated products based on Sodium Sulphite, DEHA (Diethyl Hydroxylamine), Tannins, Hydrazine, etc. These products reduce the levels of dissolved oxygen and also passivate the metal surface.

Sludge/Scale Conditioners

These products react with the alkalinity of the boiler water. Hence, neutralizing the hardness of the water and preventing scale formulation. VASU offers products based on phosphate and poly-phosphate as well as poly acrylate, maleic acrylate co-polymer for conditioning of alkaline water.

Alkalinity Builders

Sometimes it is necessary to add an alkalinity booster to set right the boiler water chemistry to prevent scale formation. Another benefit of adding this pH booster is that it helps to protect the feed water tank, feed line and flew gas economizer from acid corrosion. VASU's pH booster is a high performance product for this application.

Additional Product Availability

- Multifunctional single drum product for boilers, which is a combination of oxygen scavenger, pH booster, sludge/scale conditioner and condensate line corrosion control.

- Condensate Line Corrosion Control: A single neutralizing amine or a blend of amines with different distribution ratios is tailor-made to protect various parts of the steam line. We also provide a blend of neutralizing and filming amines to protect the pipe network